Metal accessories, components and galvanic solutions

In this section you will find the Italian excellences in chemical and galvanic metalworking and the most esteemed companies in the production, soldering and assembly of metal accessories and decorations.

High quality chemical and galvanic processes are essential for the Luxury industry: combining resistance and elegance is an added value that now characterizes Luxury production in high fashion, leather goods, and footwear.

Other processes also require the same attention, in order to guarantee a final product worthy of the great Made in Italy tradition: from accessory design to the customization of ornamental costume jewellery; from the creation of leather and synthetic semi-finished products to the production of chains, buckles and buttons; from the application of small metal parts to the selection of components such as rhinestones, eyelets, zippers and studs.

The section includes many companies capable of providing nickel free treatments, thus reconciling environmental sustainability with the highest quality workmanship.

-

5.0 s.r.l.

CNC processing of High Fashion accessories

Laterina Pergine Valdarno (AR)

-

A.M.C

Made in Italy fashion accessories and costume jewellery

Rio Saliceto (RE)

-

AMPERE ITALIA

Excellence in raw materials, accessories, and industrial chemicals for the surface treatment sector

Settimo Torinese (TO)

-

Andrei s.r.l.

Small metal parts for the fashion sector

Scandicci (FI)

-

AR Galvanica

Galvanising treatments for costume jewellery, semi-finished products, and fashion accessories

Loc Quarata (AR)

-

Arpex Textiles srl

Production of shoelaces, ribbons, and textile accessories for footwear

Barletta (BT)

-

Ayron Tech

Design and Production of Metallic and Plastic Accessories for Luxury Fashion

Campi Bisenzio (FI)

-

Barnini

Accessory design and production for high fashion

Lastra a Signa (FI)

-

BC Servizi

Design and prototyping for jewellery and High Fashion accessories

Arezzo (AR)

-

Benjamins s.r.l.

Design and development of accessories for Fashion, technological objects, sports, and gadgets

Milano (MI)

-

Berti A&P

Accessories in semi-precious stones and natural materials

Scandicci (FI)

-

Biagiotti Accessori s.r.l.

Specialised processing for the metal fashion accessory sector

Scandicci (FI)

-

BY MORA

Production of High Fashion accessories

Palosco (BG)

-

Caoduro Impianti

Design and production of galvanic systems

Brendola (VI)

-

CDC srl

Production of ornamental chains for the Luxury sector

Campi Bisenzio (FI)

-

Creazioni Lorenza

Design and production of metal accessories

Figline Valdarno (FI)

-

Crisden srl

Design and production of leather accessories

Reggio Emilia (RE)

-

D&D Time srl

High end jewellery and accessories

Vicenza (VI)

-

Decò Style

Painting, special finishes, and accessory fitting

Reggello (FI)

-

EAM Lucidatura srl

Polishing and metal surface treatments

Terranuova Braccialini (AR)

-

EGAL

COMPANY LEADER IN PLASTIC AND METAL TREATMENTS

Origgio (VA)

-

F&G s.r.l.

Production of metal accessories for the fashion and furnishing sectors

Monte Vidon Corrado (FM)

-

Fatà Smalti S.r.l.

Fine workmanship for the goldsmith and fashion accessories sector

Arezzo (AR)

-

Fec Serilabel S.r.l.

Design labels with a Made in Italy soul

Grumello del Monte (BG)

-

FIBEL Group srl

Design and production of metal accessories, plaiting, and bindings for leather goods and footwear

Scandicci (FI)

-

FIMMA spa

Design, production, and electroplating for High Fashion small metal parts

Osnago (LC)

-

Florence Chiusure s.n.c.

Zamak and brass accessories for leather goods

Firenze (FI)

-

Florenradica srl

The art of giving shape to client ideas by combining technological innovation, aesthetic beauty, and functionality

Montespertoli (FI)

-

FM di Farruggio Maria

Processing and production of non- precious metal accessories

Arezzo (AR)

-

G&CO SNC

Thermoforming for handling accessories

Chiuduno (BG)

-

Galvanica Formelli

Artistic galvanic treatments for fashion accessories

Arezzo (AR)

-

Galvanica MC s.r.l.

Chrome plating of aluminium and plastic accessories for the fashion and automotive industries

Grottazzolina (FM)

-

GI.MA. srl

Fashion components

Firenze (FI)

-

Gimet Brass

Chains and small metal findings for high fashion accessories

Arezzo (AR)

-

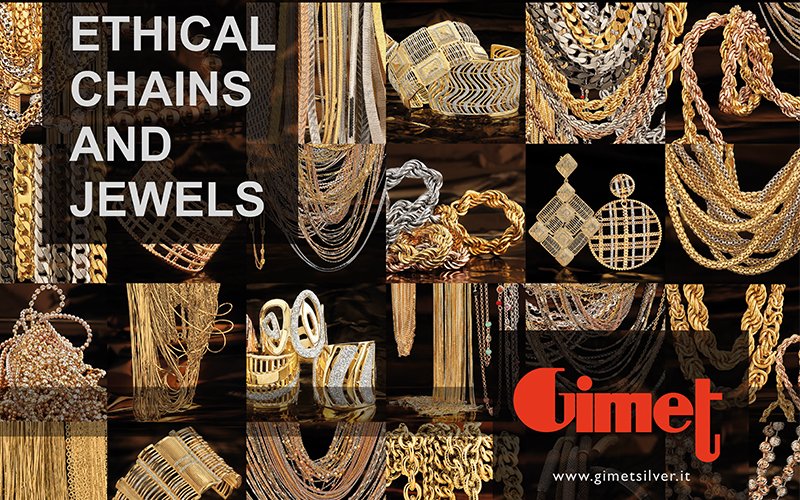

Gimet Spa

Production of silver chains and jewellery

Arezzo (AR)

-

GRIBA srl

Metal accessories for leather goods and footwear

Calenzano (FI)

-

I Fonditori srl

Microfusion semi-finished products

Civitella in Val di Chiana (AR)

-

Il Crogiolo snc

Metal modellers

Scandicci (FI)

-

Il Gioiello di Fiume s.r.l.

Production of metal accessories and jewel bags for the fashion industry

Arzano (NA)

-

International Leather Weavings

Fucecchio (FI)

-

Italfimet srl

Chemicals, plant and electronics engineering: turnkey electroplating

Monte San Savino (AR)

-

Italiana Accessori srl

On a journey with the client towards excellence

Montevarchi (AR)

-

Itar s.r.l.

Metal accessory, crochet, and knitwear production for the FASHION industry

Montegiorgio (FM)

-

J-VAL

Design and production of metal accessories for the fashion sector

Grumello del Monte (BG)

-

Jessica Jewels

Accessories and jewellery for High Fashion

Ponticino (AR)

-

Joker Preziosi

From the processing of precious metals to the production of semi-finished gold products

Civitella in Valdichiana (AR)

-

Kometa srl

Production of silver and metal jewellery and accessories

Monte San Savino (AR)

-

Lampa srl

When quality rhymes with sustainability

Grumello del Monte (BG)

-

Lampo by Ditta Giovanni Lanfranchi S.p.A.

A product between quality and sustainability ready to conquer the market

Palazzolo sull’Oglio (BS)

-

Landi

Finishes and galvanic treatments for fashion accessories and small metal and plastic parts

Campi Bisenzio (FI)

-

Lartigianabottoni spa

When the spirit of artisanship meets the power of industrial innovation

Bolgare (BG)

-

Laura Del Siena

Fine workmanship for the goldsmith and fashion accessory sectors

Arezzo (AR)

-

Legor Group spa

Specialists in metallurgy and chemicals for fashion accessories

Bressanvido (VI)

-

LR etichette

Production of barcode labels for footwear, leather goods, and apparel

Poggibonsi (SI)

-

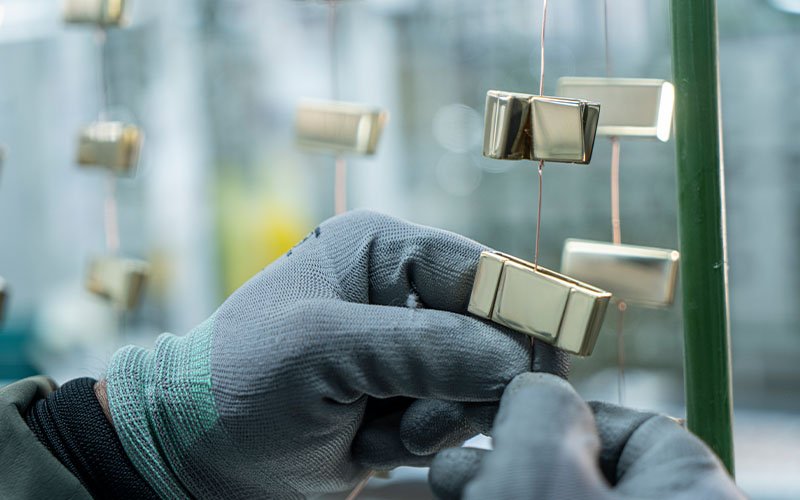

M.F. di Mascagni & Fagioli

Soldering and assembly of metal accessories

Levane (AR)

-

M.G. Galvanica

Electrolytic treatments and galvanic finishes for fashion accessories

Castiglion Fiorentino (AR)

-

Macuz snc

Accessories for High Fashion

Firenze (FI)

-

Materia Firenze s.r.l.

The design and manufacture of metal accessories for High Fashion

Scandicci (FI)

-

MBA F.lli Landi srl

Design and manufacturing of customized small metal findings for the leather goods sector

Greve in Chianti (FI)

-

Meoni & Ciampalini spa

In stock accessories for garment, leather goods, and footwear production

Empoli (FI)

-

Mercato Group Accessori Srl

Production of metal accessories for bags, footwear, and furnishings

Napoli (NA)

-

Metallinea

Design, development, and production of accessories

Bagno a Ripoli (FI)

-

Metalmoda srl

Design and creation of accessories for High Fashion

San Giovanni Valdarno (AR)

-

Metalplus

Production of metal accessories for the fashion industry

Scarperia e San Piero (FI)

-

Micromet Srl

Semi-finished metal in lost- wax precision casting for high fashion

Arezzo (AR)

-

Miperval Spa

Production of metal fashion accessories

Arcisate (VA)

-

MMC Colombo

Small metal goods, articles for luggage, leather goods, and leashes

Varese (VA)

-

Modimex Accessori srl

High Fashion accessories

Osmannoro (FI)

-

Moro Minuterie srl

Metal accessories for footwear and leather goods

Padova (PD)

-

Nastro Elle

Single and double-sided tape production

Empoli (FI)

-

OMS Italia

Made in Italy pressure eyelets

Pontassieve (FI)

-

Orchidea Preziosi Srl

Technology and expertise in precious metal processing

Arezzo (AR)

-

PFM Accessori Srl

Production of carabiners and metal accessories for leather goods

Arezzo (AR)

-

Picador S.r.l.

The metal specialists, from the gold districts to leather goods

Arezzo (AR)

-

Ramponi spa

Studs, stones, rhinestones, embroidery, fashion accessories, and plastic moulding for High Fashion

Carbonate (CO)

-

Ricamificio La Perla di Bellacci B. & C. Snc

Embroidery, accessories, appliqués, prints, and hand-painted decorations

Laterina Pergine Valdarno (AR)

-

Roberto Poggiali

Artisan goldsmith workshop with industrial production

Firenze 50126 (FI)

-

Santoni Stampaggio

Thermomoulding technologies

Rapagnano (FM)

-

Serena Cecchini Design

If you can imagine it, Serena Cecchini Design makes it happen with style

Lucca (LU)

-

Smaltart

Enamelling for leather goods and jewellery

Firenze (FI)

-

Spazio 58 S.r.l.

Production and processing of metal accessories for footwear and leather goods

Sant'Elpidio a Mare (FM)

-

Superlativa

Extra luxurious and eco-friendly mother-of-pearl fabrics

Passirano (BS)

-

Syscam

Dealer and developer of 3D modelling tools

Antella (FI)

-

Taurini Pianeta Gemme

Refined and exclusive materials from every part of the world

Scandicci (FI)

-

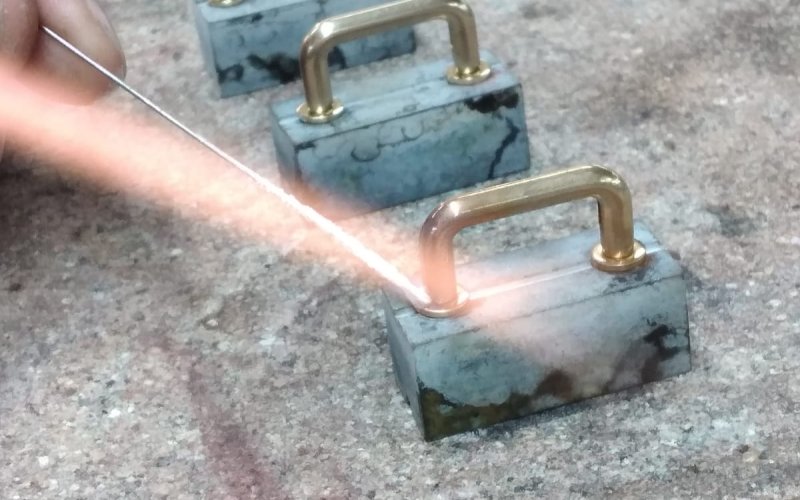

TR SRL

Weldindg small parts and accessory creation for leather goods and high fashion

Barbarano Mossano (VI)

-

Uber Plants Italia

Terranuova Braccialini (AR)

-

V.A.M.P. s.r.l.

The Italian excellence of metal fashion accessories: VIOLA

Palazzolo sull'Oglio (BS)

-

Vibert Italia SRL

Commerce of accessories for footwear and leather goods

Montelupo Fiorentino (FI)

-

Vilux by TR srl

Lost-wax casting for metal accessories

Vicenza (VI)

-

Wealth srl

Design and supply of small metal parts and accessories for the world of Fashion

Desio (MB)