News

In the eye of the needle: how do you sew a luxury product?

Daniele Orlandi, teacher at Mita in Scandicci and commercial director of Del Vecchia Group

"Unlike in the past, today brands use many different materials, which is why it is important to teach kids how to find the right solutions in the shortest time possible, or rather in the 'zero time' that the system dictates". Daniele Orlandi, professor of Materials, components and production cycles at Mita in Scandicci and commercial director of Del Vecchia Group, explains what guides the choice of machinery, needles and solutions in the creation phase of a product intended for the luxury fashion sector.

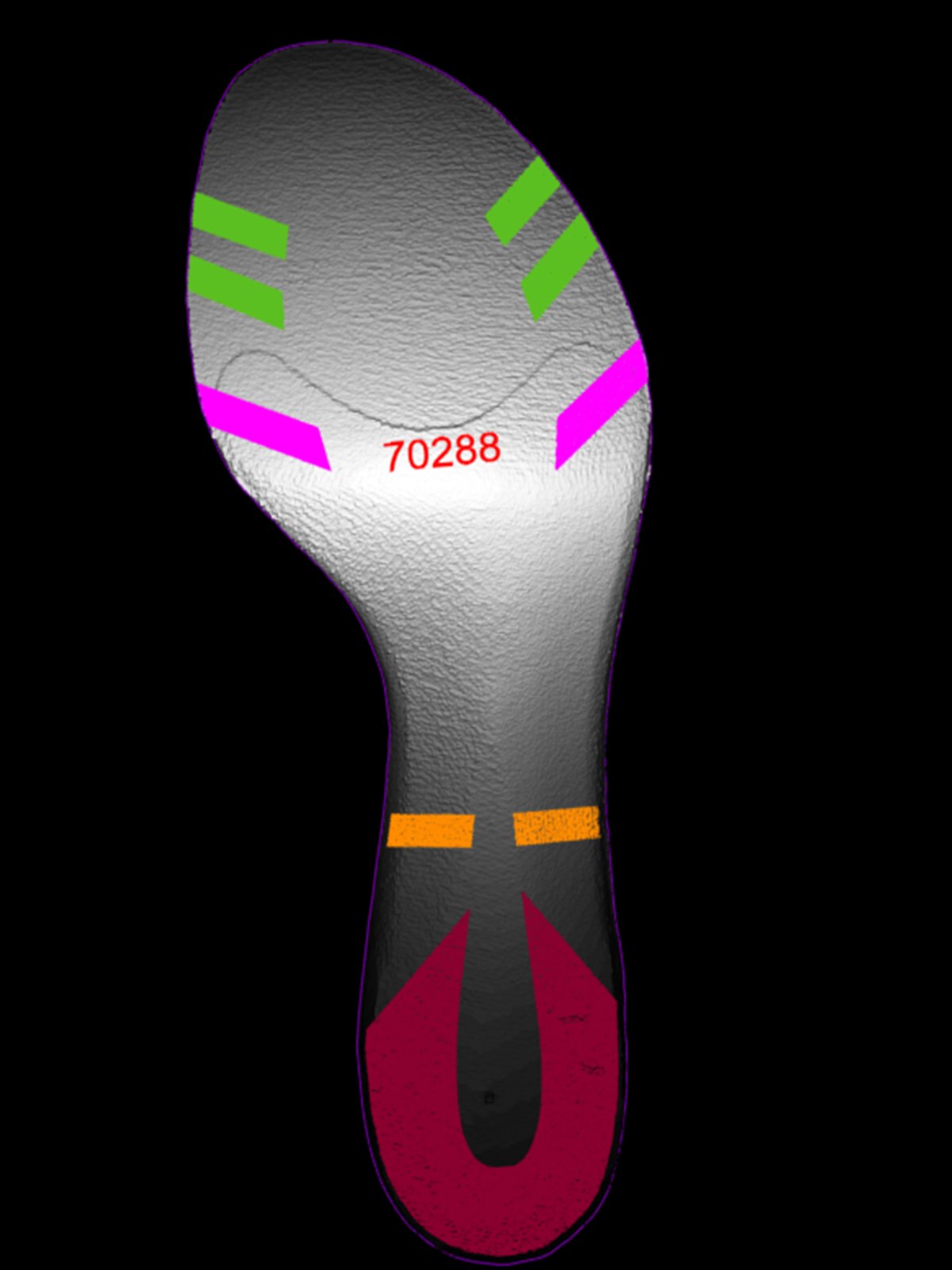

«The machinery to be used is chosen based on the shape of the object – he explains -: when the style office delivers the model to be created to the company, it is first of all necessary to engineer the project, that is, to develop the phases necessary to create the individual pieces that will compose it." There are many variables to consider: for example if the production involves hand sewing, this will create a major bottleneck in the production process: for this reason it is necessary to provide them with all the skills that can be summarized in problem solving.

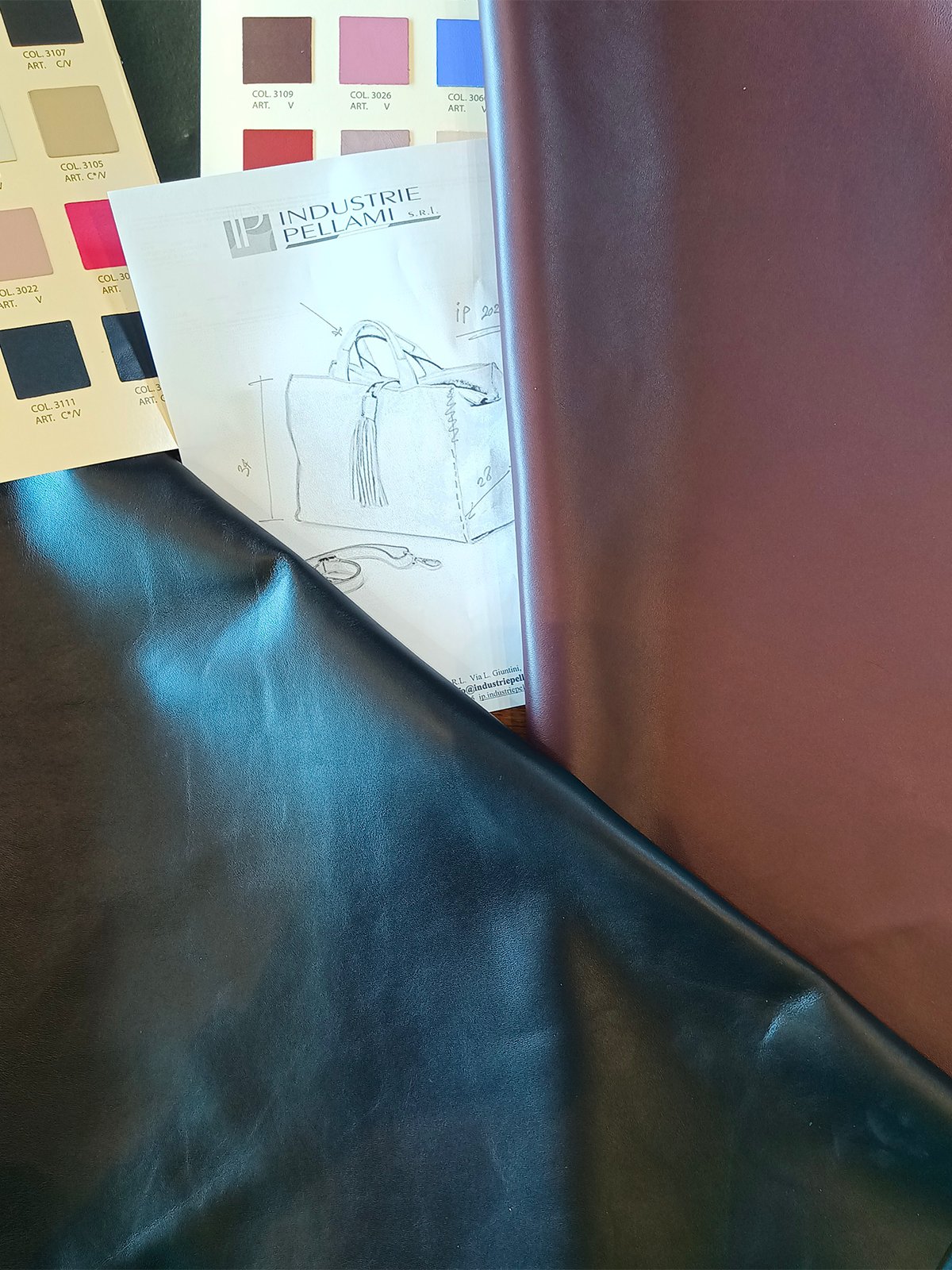

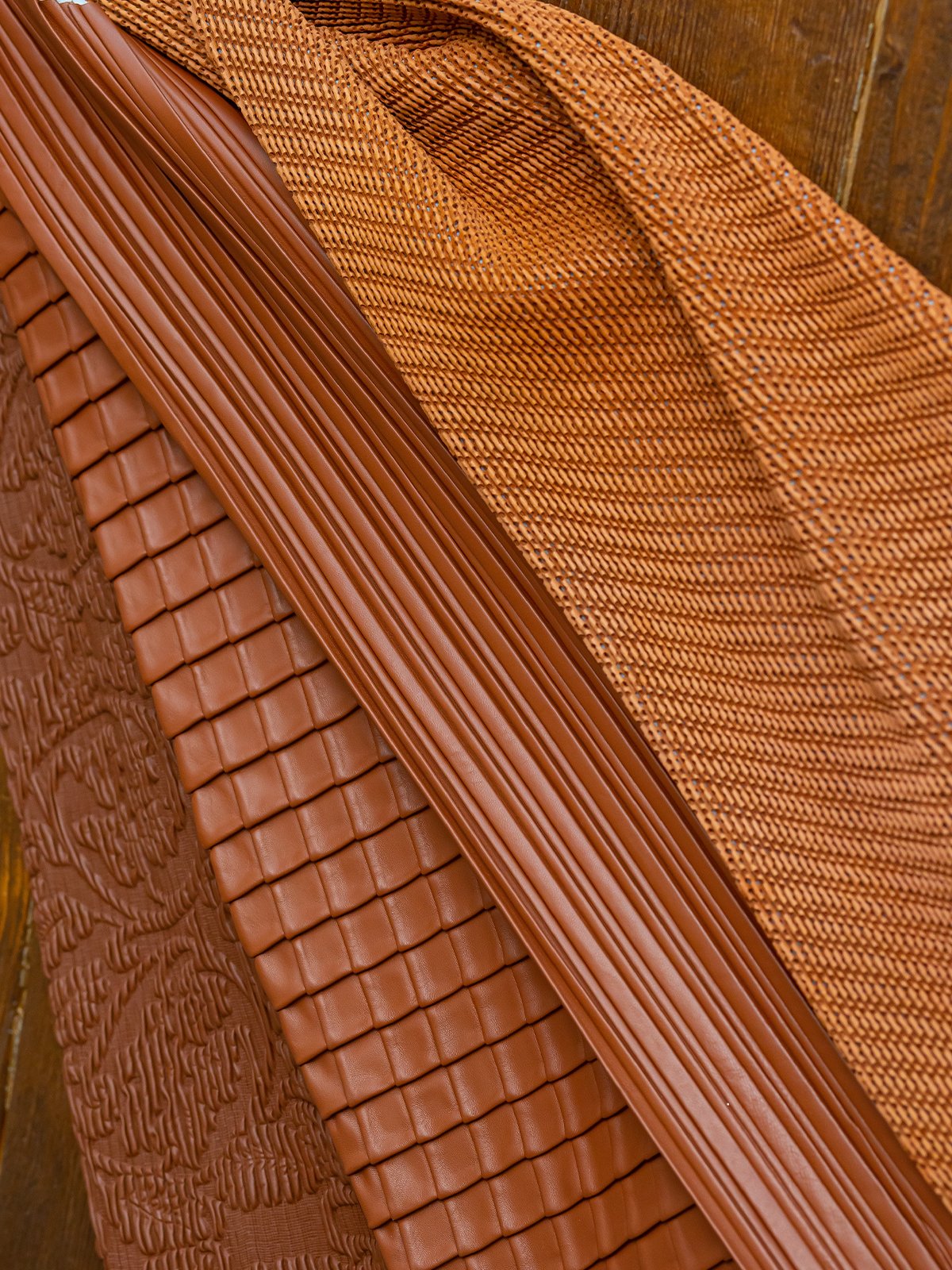

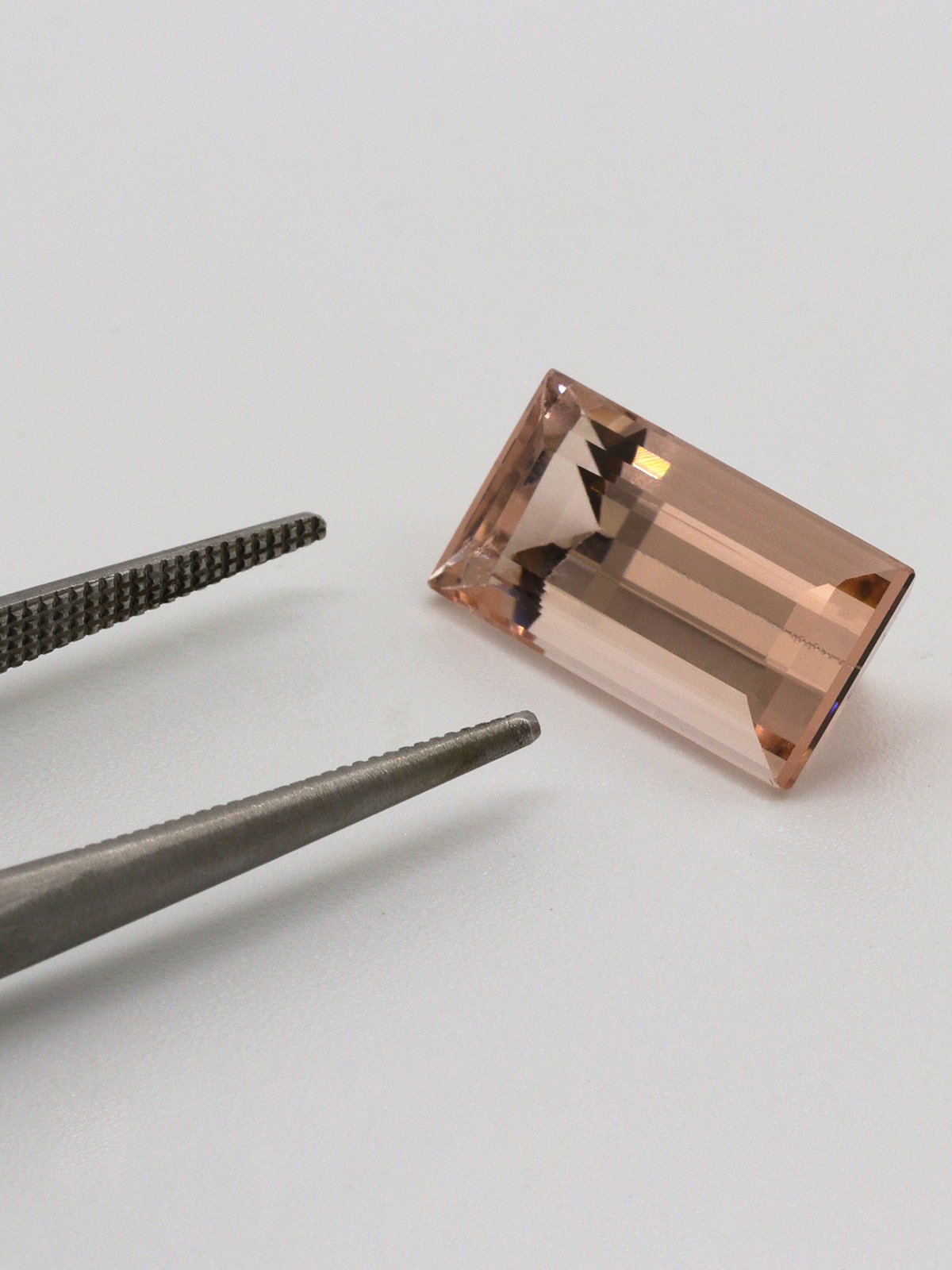

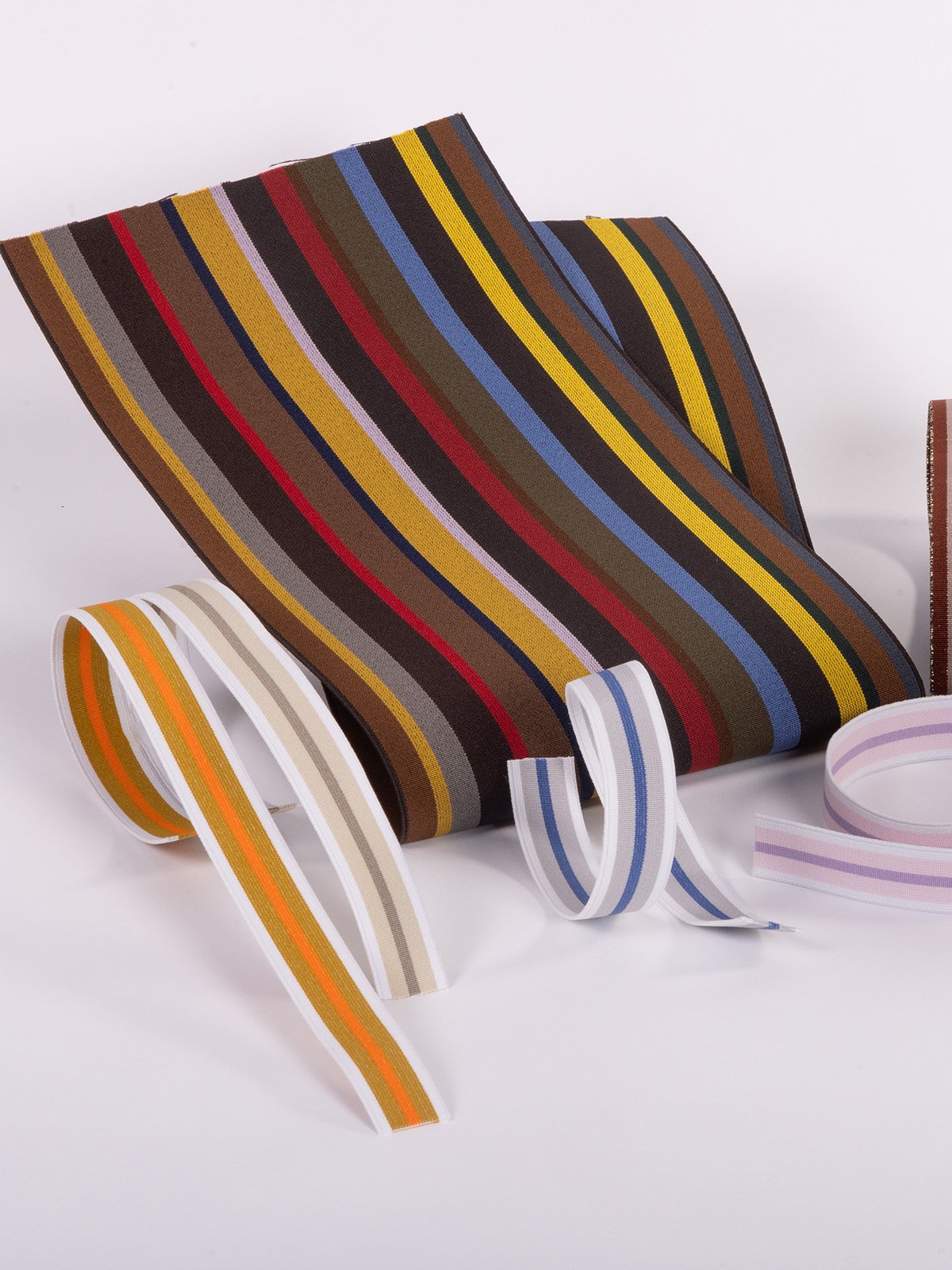

Regarding the choice of needles, the issue becomes even more complex. "The choice of needles is closely linked to a peculiarity that the sector is taking on. All luxury brands are undergoing changes in management and style, which have repercussions on products and materials. Compared to ten years ago, when we tended to always use the same leathers and fabrics, today the materials managed by the supply chain are many and very different from each other. Suffice it to say that in his latest collection Alessandro Michele proposed more than 200 items, all in different variations."

On the leather goods front, there are other specificities to respect. "In leather goods we talk about stitching, not stitching; a detail that defines the quality of the object. Usually the thread is over-coloured, highlighted precisely to distinguish its quality. When the needle impacts the skin, if it is not chosen well and is not combined with the right thread and the right machinery, it creates a split, generating a defect which is the first thing you notice. To avoid these errors there are also needles created specifically for a single process."

And in this sense Mita represents a creative hotbed. "The comparison with kids also offers the possibility of analyzing the way in which the products behave. It is a school that is not subject to innovations but represents a real testing ground for machinery and components: by testing and looking for solutions it is possible to achieve the quality standards that the luxury sector requires. Each case is approached with a new approach and sometimes truly brilliant solutions emerge."