News

Self-generated energy and sustainable approach: Ramponi's challenges

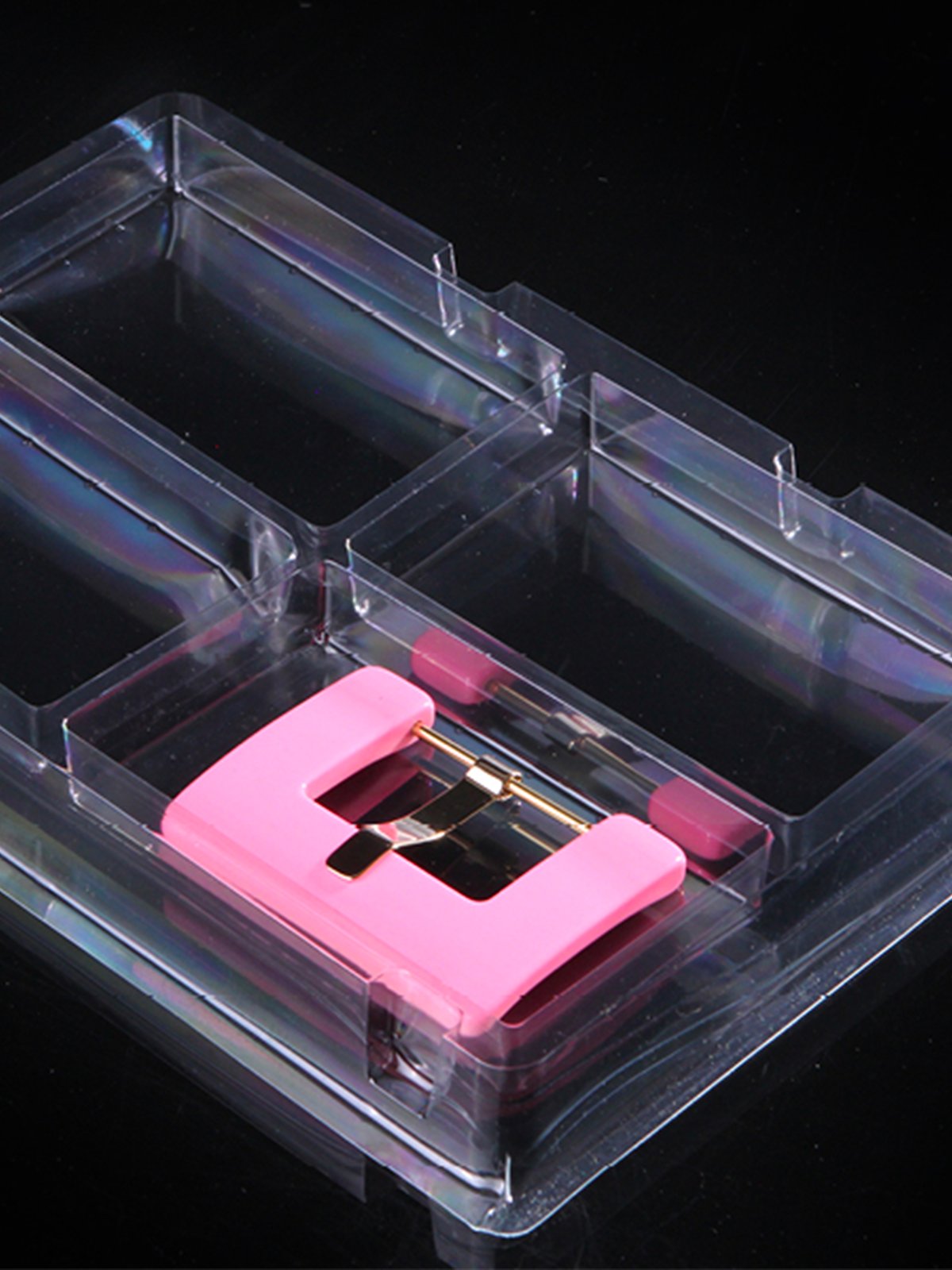

Balance between technology, man and nature. This is the great challenge of Industry 5.0, which identifies resilience, the centrality of the individual and sustainability among its pillars. With this in mind, the choice of Ramponi (Carbonate, CO), a company specializing in the manufacture of studs, rhinestones and stones, proves topical: to draw up an annual social report and to establish the function of Sustainability Manager in the corporate organizational chart. "Our sustainability concept embraces the three ESG pillars," explains Elisabetta Cacioppo, Sustainability Manager at Ramponi, "and although we would not be obliged to report our data, we wanted to put our commitment in black and white. Our Report is available to all interested parties, on our website www.ramponispa.com."

Ethical action takes place on a number of fronts, from allocating resources for digitization and training to charitable initiatives, including careful evaluation of suppliers and responsible use of resources. In addition to general principles on welfare and union rights, the company has also introduced a number of activities to improve the quality of life in the company. A responsible way of doing business that also aims to contribute to the improvement of the area in which Ramponi operates: already UNI ISO 9001:2015 and UNI ISO 45001:2018 certified, the company has set the goal of obtaining environmental certifications by the end of 2023.

Turning to the numbers, in 2022 22 percent of the company's energy consumption is derived from self-generated energy thanks to the 800 square meters of photovoltaic panels installed, while the remaining 78 percent comes from a supplier that uses 100 percent energy from renewable sources. The company periodically monitors its atmospheric emissions: concentrations for 2022 were also well below limits. Ninety-seven percent of waste related to plastic molding is recovered, collected, ground, and fed back into the production cycle.

Ramponi's sustainable approach covers both processes and products. Alongside traditional raw materials such as Abs and Pmma, it has in fact introduced into its lines accessories from Bio-Based materials such as Pla (Thermoplastic polyester acquired 100 percent from renewable sources, compostable and recyclable), Eco Pe (bioplastics obtained from wood) and recycled nylon. On the finishing front, it uses partners who submit annual declarations of compliance, especially on the use of toxic process fume abatement equipment.

The packaging material used in the company, is certified 100% recycled and recyclable and all the suppliers it uses are verified and required to adhere to the principles of legality, ethics and good practices contained in the Ramponi Code of Ethics.