News

The ecological transition of the Fashion supply chain goes through the recovery and proper management of industrial waste

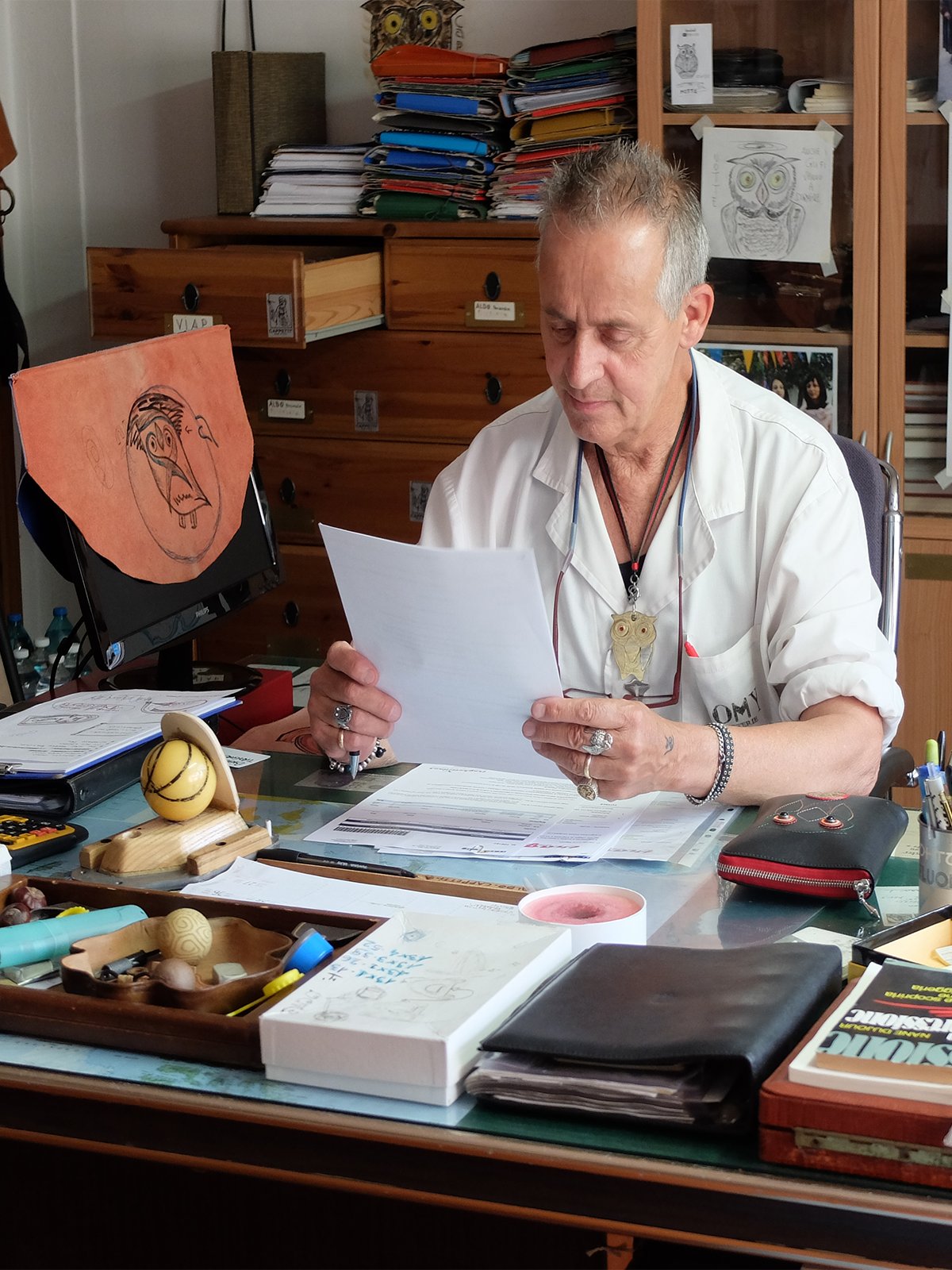

According to the latest data from the Istituto Superiore per la Protezione e la Ricerca Ambientale (ISPRA), the production of special waste from all manufacturing activities in Italy for the year 2020 was about 26.7 million tons, 18.2 percent of the total. Recovered waste accounted for 82.1 percent of the total managed (amounting to 131.3 million tons), while waste sent to disposal operations stood at 17.9 percent. The Fashion supply chain is central to the implementation of the circular economy under the European Green Deal and the Next Generation EU: cornerstones of the ecological transition include expanding the waste recovery network and diversifying waste management solutions. Accelerating the process of waste valorization has also been taken care of by legislation: as of January 1, 2022, separate collection of textile waste and scrap is mandatory in Italy (D.Lgs.116/2020), planned at the European level by 2025. For the textile products chain of clothing, footwear, accessories and leather goods, two other important changes are coming in the next few days: the Ministry of Environment and Energy Security has announced a measure that will establish extended producer responsibility, which will have to take charge of "the financing and organization of the collection, start-up for preparation for reuse, recycling and recovery of waste from textile products" and will also have to develop, produce and market products "suitable for reuse and repair, containing recycled materials, technically durable and easily repairable." There is also a 450-million-euro financial contribution earmarked for 65 innovative projects to build or modernize waste treatment plants for leather, textile, wastewater sludge and absorbent materials for personal use. Therefore, it is becoming increasingly central not only to manage waste correctly, but to think along the lines of the Green Economy and commit to recovering the raw material and reintroducing it into the production cycle. This is the vision of Roberto Lo Presti, an environmental biologist at Selin Srl, a company specializing in the management of hazardous and non-hazardous industrial waste: "We provide comprehensive consulting to companies in the fashion sector on the valorization of waste, the development of methods and strategies to save resources and costs starting with the reuse and recycling of raw material." In 2022, companies in the Florentine Fashion district supported by Selin produced about 2,500 tons of waste, consisting mainly of leather and packaging waste, including paper and wood. Of these, about 400 tons were hazardous waste, including glues and dyes, soaked felts and jars that contained them.The percentage of recovery (including waste-to-energy) out of total waste stands at 85 percent, compared with 15 percent that ends up in landfills. "The first step," continues Lo Presti, "is to educate people on the correct and conscious sorting of waste. This results in the decrease of material that ends up in landfills, safeguarding the environment, productive sustainability, without neglecting the considerable economic savings for companies."

How can leather scraps be recycled before they end up in landfills?

"In addition to being used to create regenerated leather, The residues of hides and skins can be used for the production of fertilizer, through a process of protein hydrolysis, to increase the fertility of soil used for organic farming. Of course, to do this it is necessary that the leather does not contain mastics, glues or pvc films, so it is essential to train company staff in proper waste sorting and management."

As for textiles, what avenues do we have?

Also for textiles, wherever possible, reusing offcuts to create new yarns is essential. In addition, it is possible to recover plastic fibers contained in synthetic fabrics and to recover 100 percent of wool. Irrecoverable scraps, which would otherwise end up in landfills or at the incinerator, can be used to create sound-absorbing acoustic panels and bricks for the construction industry, or as fuel for cement plants.

How can Fashion companies prepare to take the plunge into sustainability?

"Fundamental is proper environmental and waste management consulting, where Selin is a partner of choice. Also central to sustainable waste disposal is choosing suppliers who can manage the waste locally, creating less impact in terms of transportation, pollution and costs. Making sustainable choices means first and foremost being aware of the impact that one's company has on the territory: we are working to provide our customers with the carbon footprint, which highlights the total CO2 emissions associated with the company's activities, with the possibility of offsetting them by joining social and environmental protection projects, such as reforestation projects, coastal reconstruction and implementation of renewable energy."