News

Chi Ri-Cerca Trova: But is fake fur really environmentally friendly?

New appointment with the Leather&Luxury column, a journey in search of innovative materials, techniques and processes, undertaken with the designer Bettina Grampa.

In 2018, numerous environmental protection organizations launched a boycott on the use of animal fur on a large scale, and some luxury brands chose to abandon its use permanently to avoid public attacks; they chose to use fur made of acrylic fibers and plastics out of "ethical sense."

But is fake fur really environmentally friendly?

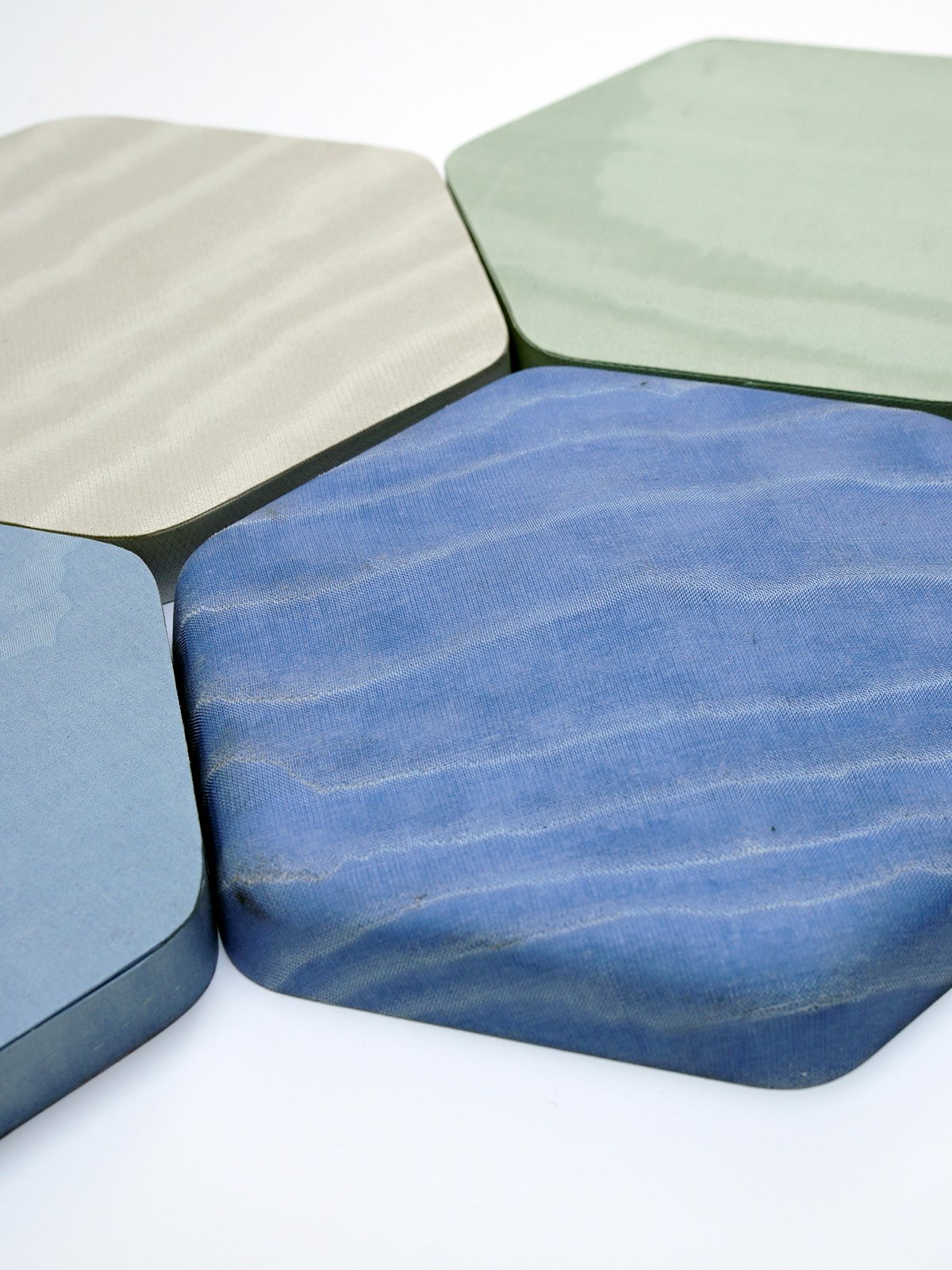

After careful testing, it has been determined that the degradation time of faux fur can take hundreds of years and that its dyeing process is extremely harmful, and as a result, the call has come inexorably to boycott its use as well. Since 2020, some clothing and accessories manufacturers have chosen to sign an afur-free agreement and completely abandon all fur. In addition, it should be noted that in recent times, some companies have attempted to produce fabrics (jersey, sponges, etc.) similar to fur but made from recycled material and without the characteristics of the "technical construction" typical of a traditional fur, a truly innovative leather/fur effect. Having made these due introductions, let us now talk about Xue Chen who, in 2018, learns and deepens his technical knowledge of animal fur construction at SAGA FURS precisely because of his love for this material, while also understanding the cruel and if you will, inhumane aspect of using animal fur. Between 2018 and 2021 he then explored new techniques for what would become his graduate project.

"Inspired by hair transplant surgery, I began to wonder if it was possible to grow even the fake fur on fur. Faux fur has to use plastic and acrylic fibers because of the production limitations of weaving technology. Therefore, I collaborated with a wig factory and decided to replace the needles of computerized embroidery machines with specific needles for hair implantation, implanting PLA fibers used for toothbrushes into the skin. In 2021 I also began studying Bio-design, devoting myself to the exploration of bio-fur. I have practically always been trying to think of a winning ecological solution to be able to make garments without the use of animal fur, a product that could also be degraded to the ground. Technically, fur is divided into 2 parts: the skin and the fur. I then used expired beverages by mixing them with additives from the world of "food," resulting in a polyurethane-like coating that I applied to a sustainable base in order to make a bioskin. The fur part, on the other hand, was obtained from weed plants grafted onto the bioskin. This fiber obtained from the plants can also be used to create a knitting yarn. I initially wanted to use regular plant fibers, but after reading up on the ecological impact of cotton cultivation, wool production, and other fibers, I realized that using them did not make sense. After much research, I decided that weeds were the best option, an effective way to combat biodiversity loss and INNS. This process is not only ecologically beneficial, but also creates added value for the fashion industry. Invasive non-native species (INNS) are in fact one of the top five threats to biodiversity worldwide. On average, INNS cost the UK economy £1.8 billion a year, mainly affecting agriculture, forestry, horticulture, utilities, construction, and sports infrastructure. These plants also contain many natural pigments and are rich in plant cellulose."

Xue Chen continues:

"My goal was to obtain 'transplanted' fur that was a perfect replica of animal fur. As an undergraduate student, I invented the technique that fully simulates animal fur by transplanting the hair and modifying the needles of a computerized embroidery machine, a technique that is very popular in the wig-making industry. The technique produces a hair with no trace of production on the front. In addition, this implanting technique allows placement on garment based on the shape of the garment. After three years of exploration and experimentation, the wig factory I worked with has since deepened and perfected this technology."