News

Legor 3D Metal Hub: the innovation center dedicated to 3D Printing for the luxury industry

Legor, a multinational group founded in Italy in 1979, is a specialist in metallurgy and chemistry that - by developing the value chain and production processes with a view to Sustainability - transforms metals into alloys, galvanic solutions and powders of excellence for the production of jewelry and fashion accessories. In addition, Legor is the first and only company in the industry to certify that its products are made solely with precious metals from 100% recycled sources and entirely from a controlled supply chain, certified by the Responsible Jewellery Council's Chain of Custody.

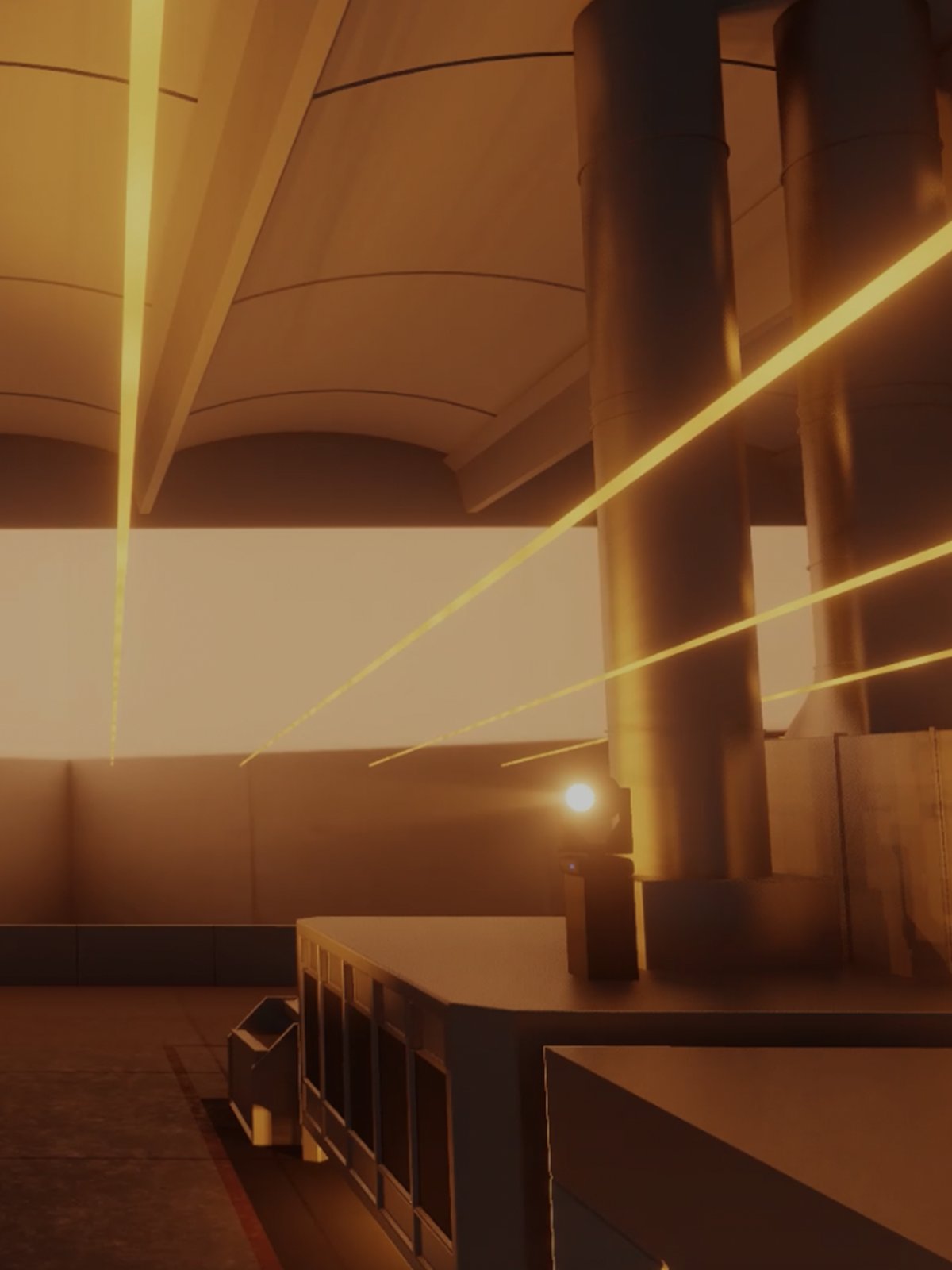

Today, progress, innovation and sustainability come together to give birth to the Legor 3D Metal Hub: an innovative hub whose purpose is to experiment with and produce jewelry and fashion accessories from precious and non-precious metal powders using the revolutionary Binder Jet technology.

3D printing with Binder Jet technology is an alternative method to classic investment casting that does not require the burning of waxes or resins, nor the use of plaster, for increasingly sustainable production processes.

This technology is an alternative to SLM (Selective Laser Melting) and MIM (Metal Injection Molding) technologies, presenting several benefits:

- Better surface quality than SLM

- Simpler and more economical process compared to MIM

- Speed of printing

- No support at the printing stage

Collaborating with major players in the industry, Legor, the first company to introduce this new technology, intends to make the advantages of additive manufacturing available for the development of new solutions in the jewelry and fashion accessories industry, combining flexibility and creativity with productivity optimization.

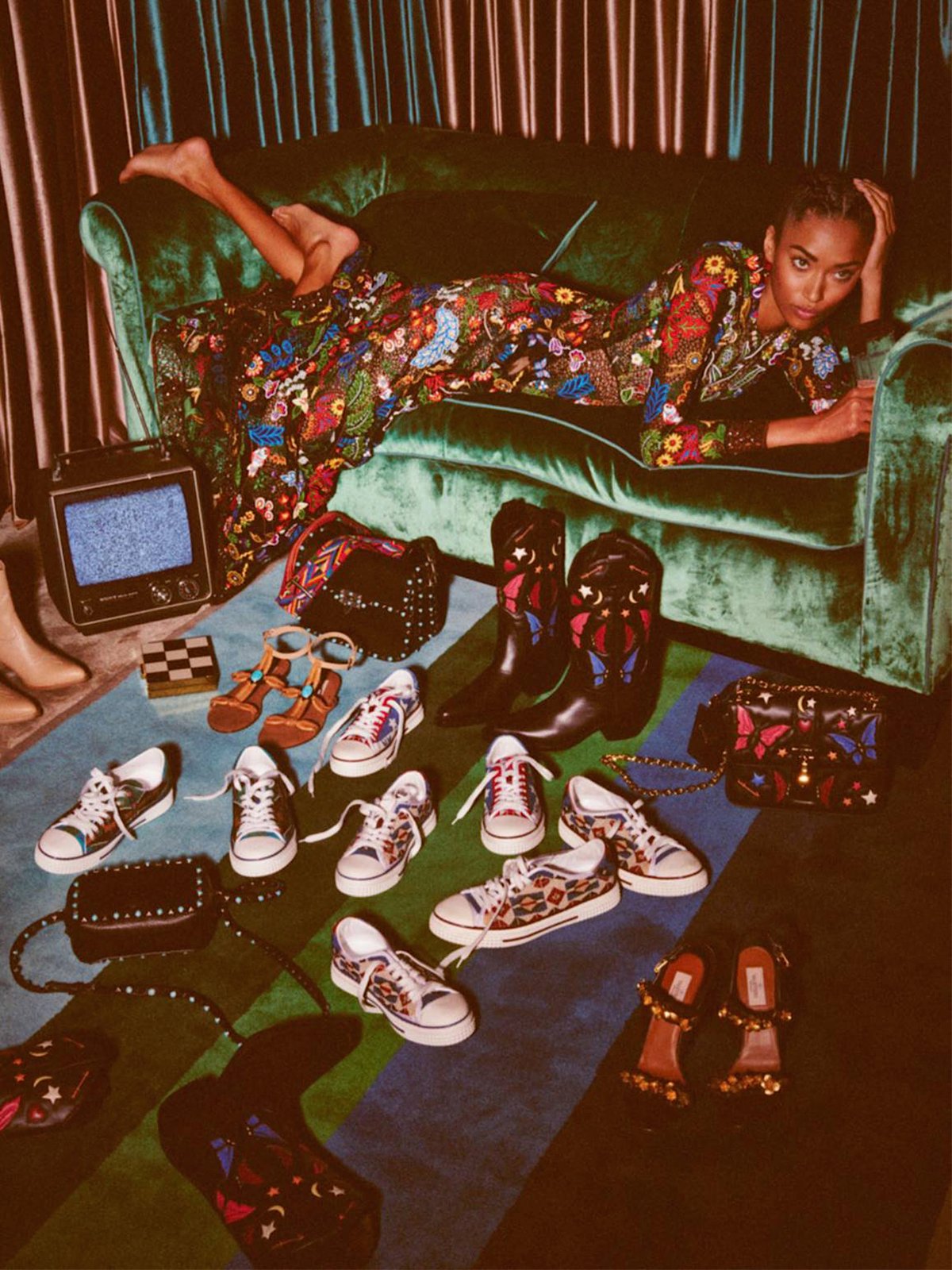

Starting with the 3D production of stainless steel accessories for the fashion and luxury industry, Legor is also engaged in the development of materials and solutions for the creation of 3D parts in precious metal, such as silver, and non-precious metal, such as bronze-which it will be experimenting with in the 3D Metal Hub in Italy-in order to enable the production of large-scale, cost-competitive and fast parts.

Finally, to meet the needs of 3D printing and its future adoption on a large scale, Legor has developed Powmet: a line of metal powders that is atomized through an exclusive process that allows obtaining perfectly spherical, extra-fine and homogeneous particles with uniform chemical composition and low impurity content. From precious title powders of gold, silver and platinum alloys to non-precious title powders of bronze and copper alloys.

Choosing Legor means choosing high technology and the reliability of a Made in Italy product with responsive worldwide service.