News

Italconcia and Herambiente together for Be Future: an innovative circular economy project

An innovative project for a completely green leather

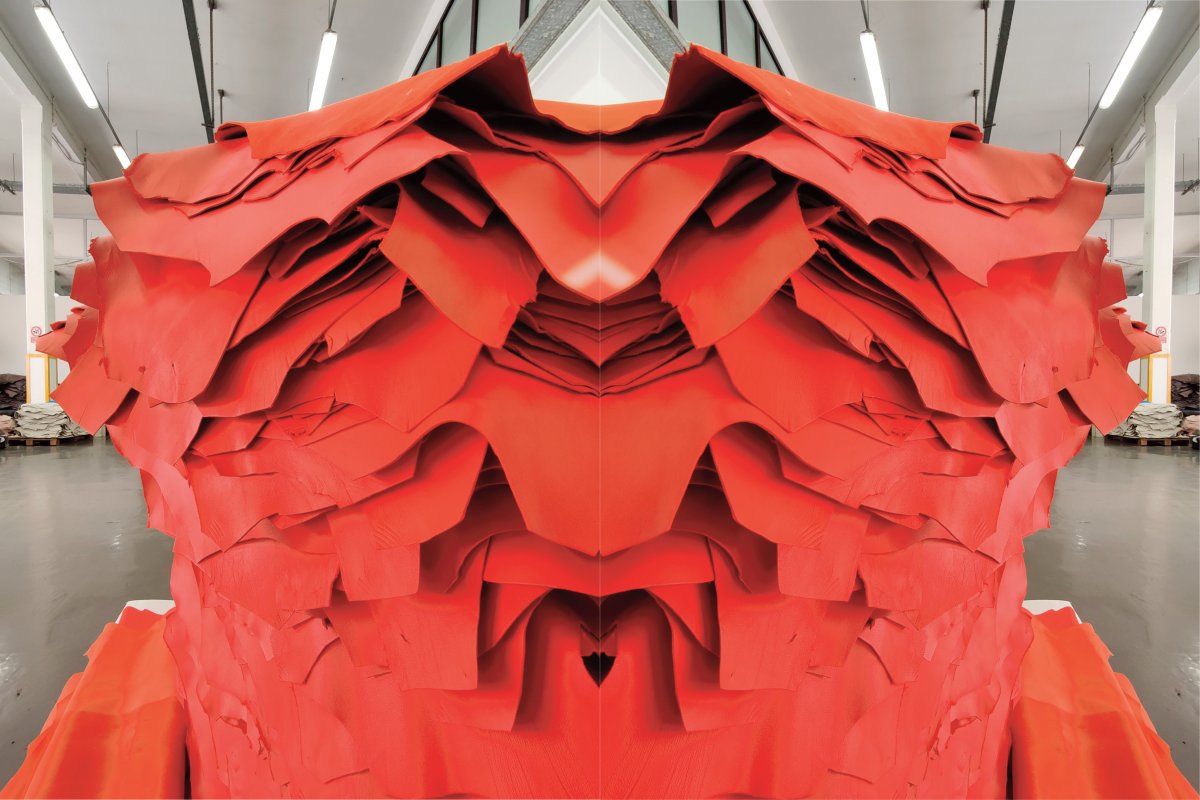

The highest quality leather, tanned without the use of fossil energy sources and products from the petroleum industry, is not enough. Starting tomorrow, that leather will give rise to a circular economy project, on a very large scale. The project, called Be Future, is by Italconcia, among Italy's leaders in high-end leather tanning, which, thanks to its collaboration with Herambiente Servizi Industriali (Hera Group), is moving forward the frontier of sustainability in the tanning sector, anticipating what is required by European legislation.

Collecting waste from all Italconcia customers and sending it for recovery

Italconcia has developed an innovative tanning process that, among other things, substantially excludes the use of fossil-based substances and substances harmful or damaging to humans and the environment in processing. The leather, branded BBL - BioBasedLeather®, is used by some of the world's most prestigious manufacturers of luxury footwear and leather goods. Thanks to the agreement with Herambiente, all industrial waste from BBL leather will be collected and sent for recovery to produce high-quality fertilizer. This will be done not only at the Italconcia plant in Castelfranco di Sotto, but also at all Italconcia customers in Italy.

Integration with the value chains of high-end manufacturers

The truly innovative aspect of the collaboration is precisely the integration of recovery into customers' value chains. In fact, it will be Herambiente that will engineer the separate collection of BBL - BioBasedLeather® leather, in the customers' plants (as well as Italconcia's), take care of its transport to the platforms of Castelfranco di Sotto and Torbelvicino (at the headquarters of the subsidiary Vallortigara Servizi Ambientali), carry out the commodity controls and deliver the waste to selected fertilizer producers.

Fertilizer for nurseries: an almost zero-kilometer recovery

Somewhat like bags, jackets and shoes, the fertilizer produced from BBL - BioBasedLeather® leather will also be of the highest quality. In addition to being used in agriculture, it will also be destined for Tuscan nurseries, closing the circle of recovery entirely, within a radius of a few kilometers.

Martini, Italconcia: "Project part of a broader commitment to sustainability"

"Be Future is part of a broader Italconcia commitment to sustainability," explains Andrea Martini, general manager of Italconcia. "It is a path that is the child of regulatory developments, but also of a deep awareness of the environmental challenges we face. For this reason, in conceiving BBL - BioBasedLeather® leather, we imagined from the outset that we would also integrate its recovery, in order to offer customers a doubly sustainable product: with zero fossil substances and that transforms raw material into second raw material, generating value in a circular economy process."

Valentini, Herambiente Industrial Services: "A partnership in line with our strategy: to be a driver of the circular economy"

"Herambiente has enthusiastically joined the project proposed by Italconcia, because our guiding value in waste management is to maximize resource recovery," explains Gianluca Valentini, General Manager Herambiente Servizi Industriali. "In this case then the environmental value of the collaboration is also combined with the contribution for a made in Italy, not only synonymous with quality and beauty, but also with sustainability."